UNDERCARRIAGE SOLUTIONS FOR THE MINING INDUSTRY

Mining is the toughest enviorment earthmoving machines can operate in. Mining machinery needs reliable,durable and cost effective undercarriage solutions.To meet the needs of mining profesionals we have a complete range of track chains and undercarriage components that have been built exclusively for mining dozers and excavators with enhanced peformance and durability in mind.

3 YEAR / 4,000 Hour Undercarriage Warranty

Large Dozer

Undercarriage

Big Shovel Mining Excavators

Special

Applications

Bucket wheel excavators, Reclaimer belt stackers, Transport crawlers,

Sub-sea diamond dredger, Mobile crushers, Conveyors

This is the toughest environment earthmoving machines can operate in, with remote sites, difficult geological situations and often extreme meteorological conditions.Mining machinery, therefore needs to be reliable, durable and with a competitive cost per hour.

To meet the needs of mining professionals, ITM has extended its undercarriage components range, developing a new series of track chains for mining dozers. Components are lab-tested up to 2000 hours, installed and then tested in the field to ensure enhanced performance and increased durability.

OUR MOST POPULAR PRODUCT RANGE

CATERPILLAR

6018 RH90

6030 RH120E

6040/50

RH170/200

6060 - RH340

7495 - 495HRII

D8

D9

D10

D11

LARGE EXCAVATOR RANGE UNDERCARRIAGE PARTS

Explore some of the benefits our Undercarriage can provide

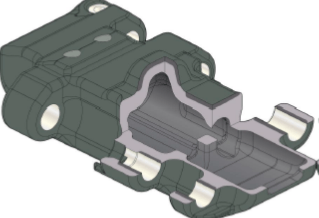

Monobloc Shoes

Main Features and Benefits

- The Monobloc Shoe is produced with special cast steel, mass heat treated for the maximum structural life in any working conditions.

- The roller path and central tooth of every single shoe are induction hardened to increase wear performance in any environment.

- Track pins are induction hardened to achieve balanced joint performance.

- The simplified retention system offers maximum reliability and serviceability for minimum machine downtime during parts replacement.

Lower Rollers

Main Features and Benefits

- Roller shell is made from special boron steel, induction hardened and stress relieved to increase robustness, guarantee high resistance and optimize wear performance in any environment.

- The roller shaft is induction hardened, realized with high surface finishing quality, to resist at heavy radial and axial loads and in the meantime guarantee an adequate internal oil lubrication.

Idlers

Main Features and Benefits

- Idler wheel is made from special cast steel, with idler rim induction hardened to increase robustness and optimize wear performance.

Sprocket/Tumbler

Main Features and Benefits

- The new sprocket are quenched and tempered plus induction hardened to obtain high resistance and, in the meantime, significantly improve wear performances in any environment.

LARGE DOZER RANGE UNDERCARRIAGE PARTS

3 YEAR / 4,000 Hour Warranty on all Undercarriage Parts

PPR Track Chains

Main Features and Benefits

- Track Chain specifically studied for machines at work on fields with high impact conditions and high loading applications.

- Track chain equipped with Heavy Duty class track links.

- Seal to bushing face contact and oil retention is significantly increased

- Made for easy maintenance demand (pin and bushing turn)

- Reduced undercarriage maintenance machine downtime

Track Rollers

Main Features and Benefits

- New Floating Seal Groups common with all other current products . These items guarantee improved Sealability and better performances at extreme ambient temperatures (both higher and lower). The parallel introduction of a new lubricant matches the increase of the item temperature operating range.

- New end collars installed guarantee improved internal seal protection and greater clamping force.

- Improved Through-Hardening shell increase the roller wear life, strenghtness and durability.

Idler Groups

Main Features and Benefits

- The design has been optimized with Finite Element Analysis using MAGMA5 software. Simulation accurately describes a cast component before production actually starts and optimizes its shape and casting process parameters to obtain quality and sound parts.

- dler wheel is made from special cast steel, with idler rim induction hardened to increase robustness and optimize wear performance.

- New Floating Seal Groups common with all other current products. These items guarantee improved sealability and better performances at extreme ambient temperatures (both high and low). The introduction of a new lubricant matches the increase of the item temperature operating range.

Sprocket/Segment Groups

Main Features and Benefits

- The sprocket segments are made with a new special casting steel, hardened and stress relieved to obtain high resistance and, at the same time, significantly improve wear performances in any environment.

- The extensive engineering activity, combined with new machining technologies guarantees the new sprocket segments series are fully interchangeable with current OEM product items.

Track Shoes / Grousers

MMain Features and Benefits

- Track shoes, obtained from heavy duty rolled steel profile (made from low alloyed Boron Steels), are through hardened and stress relieved to guarantee excellent wear, high strength and resistance to bending and breakage.

- A “Trapeizodal or Round” mud hole is provided as option to reduce accumulation of material on the track chain.

- Clipped corners are available to increase, when required from the environment the machine maneuverability and steering capacity.